Precisely Engineered E Motor Housings, DE Brackets, CE Brackets for Alternate

Housing, Connecting Rods, Clutch Housings, and Appa Patra for Demanding Applications

Established in 1996 in Faridabad, Haryana, our company has grown to

become a trusted name in the field of precision engineering and

industrial component manufacturing. With decades of expertise, we

specialize in the production and supply of E Motor Housing, DE Bracket

and CE Bracket for Alternate Housing, Connecting Rods, Clutch Housings,

Appa Patra, and a wide range of Precision Moulds. Serving diverse

industries such as automotive, electrical, mechanical, and heavy

equipment, we are known for combining technical expertise with

consistent product reliability.

Founded nearly three decades ago as a small manufacturing setup, we have steadily grown into a fully-equipped, state-of-the-art production facility. This transformation has been fueled by our unwavering dedication to innovation, quality craftsmanship, and a customer-first approach. Over the years, our commitment to excellence has earned us the confidence of OEMs, industrial buyers, and engineering professionals, who depend on our precision-engineered components to perform reliably in demanding applications.

Manufacturing Unit

Located in the industrial hub of Faridabad, our manufacturing unit is equipped with state-of-the-art machinery, including CNC machines, die-casting units, grinding equipment, hydraulic presses, and precision measuring tools. Our investment in modern technology allows us to produce components with high dimensional accuracy, consistent finish, and mechanical strength.

Our facility is divided into specialized departments:

This integrated setup ensures smooth workflows and timely execution of orders, no matter the size or complexity.

Our Team

Our success is driven by a team of qualified engineers, technicians, machinists, and quality inspectors, each with a deep understanding of materials, machining processes, and client requirements. Regular training programs and a strong focus on technical development keep our team up to date with the latest industry practices. Our design and R&D teams work in close collaboration with clients to understand application-specific needs and provide custom solutions when required.

Quality Assurance

We follow a strict quality management system to ensure our products meet or exceed industry standards. From raw material inspection to in-process checks and final testing, every product is subjected to rigorous quality controls. Our in-house lab is equipped for:

We source only certified raw materials and ensure traceability throughout the production process.

Client-Centric Approach

At the core of our operations is a deep commitment to client satisfaction. We maintain transparent communication, honor delivery timelines, and provide after-sales support wherever required. Our long-standing client relationships are a testament to our reliability and service-first mindset.

Founded nearly three decades ago as a small manufacturing setup, we have steadily grown into a fully-equipped, state-of-the-art production facility. This transformation has been fueled by our unwavering dedication to innovation, quality craftsmanship, and a customer-first approach. Over the years, our commitment to excellence has earned us the confidence of OEMs, industrial buyers, and engineering professionals, who depend on our precision-engineered components to perform reliably in demanding applications.

Manufacturing Unit

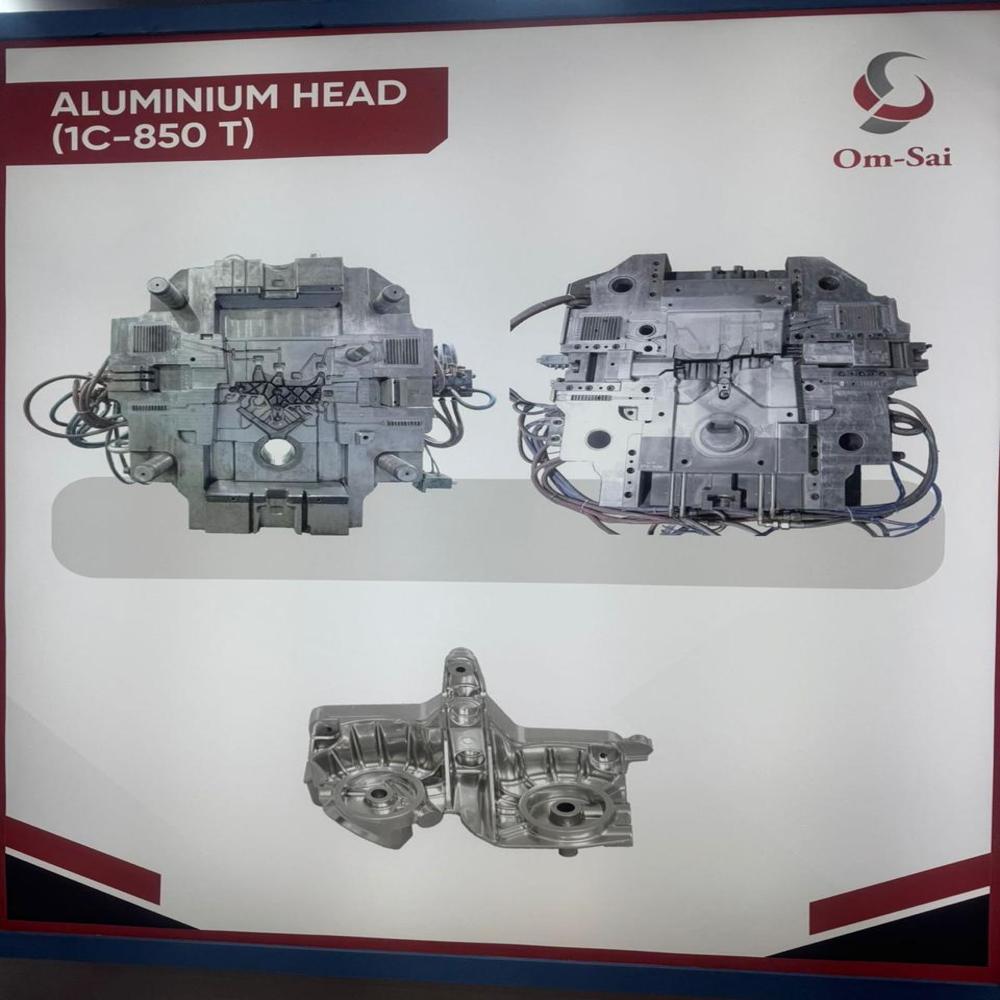

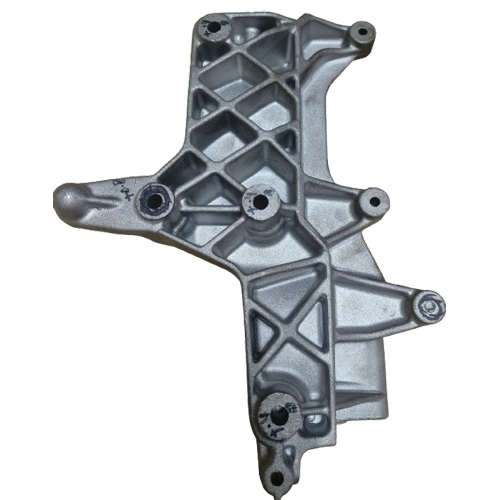

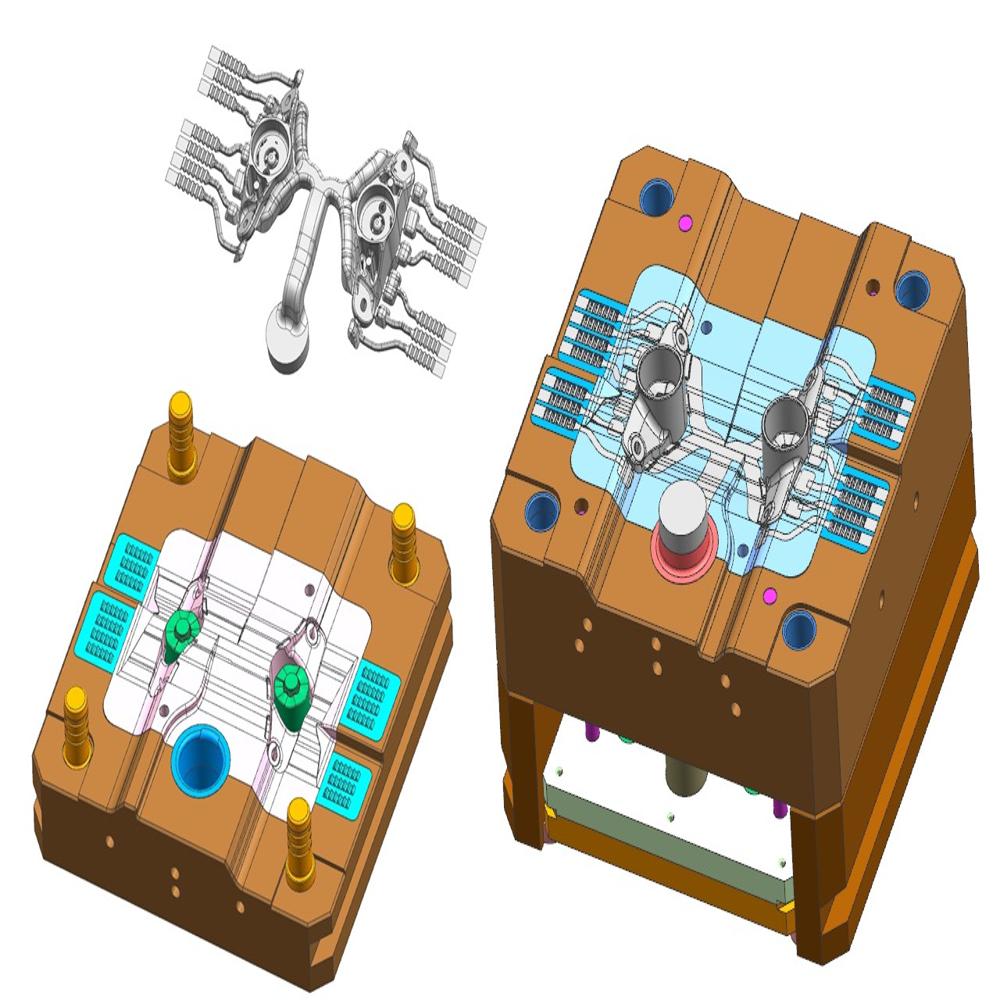

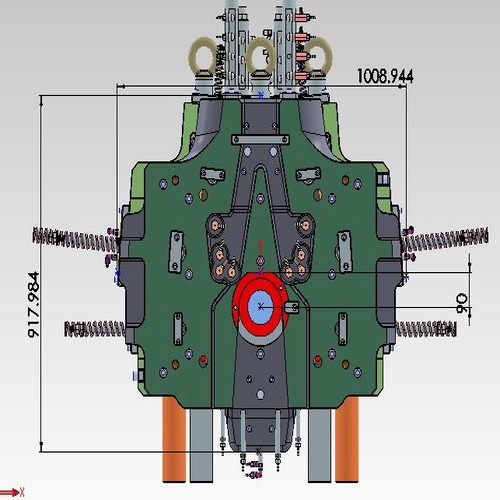

Located in the industrial hub of Faridabad, our manufacturing unit is equipped with state-of-the-art machinery, including CNC machines, die-casting units, grinding equipment, hydraulic presses, and precision measuring tools. Our investment in modern technology allows us to produce components with high dimensional accuracy, consistent finish, and mechanical strength.

Our facility is divided into specialized departments:

- Casting and Machining

- Quality Assurance & Testing

- Assembly & Finishing

- Tooling and Mould Design

- Packaging and Logistics

This integrated setup ensures smooth workflows and timely execution of orders, no matter the size or complexity.

Our Team

Our success is driven by a team of qualified engineers, technicians, machinists, and quality inspectors, each with a deep understanding of materials, machining processes, and client requirements. Regular training programs and a strong focus on technical development keep our team up to date with the latest industry practices. Our design and R&D teams work in close collaboration with clients to understand application-specific needs and provide custom solutions when required.

Quality Assurance

We follow a strict quality management system to ensure our products meet or exceed industry standards. From raw material inspection to in-process checks and final testing, every product is subjected to rigorous quality controls. Our in-house lab is equipped for:

- Dimensional Inspection

- Material Hardness Testing

- Surface Finish Analysis

- Tensile Strength and Load Testing

We source only certified raw materials and ensure traceability throughout the production process.

Client-Centric Approach

At the core of our operations is a deep commitment to client satisfaction. We maintain transparent communication, honor delivery timelines, and provide after-sales support wherever required. Our long-standing client relationships are a testament to our reliability and service-first mindset.